IEC 60664 The Fountain of Knowledge

Writing a blog that talks about “corona” may not be the most popular choice of subject based on the last few years, but the term cannot be omitted when covering this next much-demanded topic! In this blog we focus on the subject of insulation coordination and the background information that is industry independent. IEC 60664 supports high voltage automotive projects, just as it is the basis of electrical isolation in both IEC 60601 and IEC 61010 when focussing on medical or industrial standards.

We wrote a couple of blogs back in 2022 (e.g. Isolation distances are not so creepy!) focussing on the input to IEC 60601 and the definition of creepage and clearance distances. The input to these clauses in IEC 60601 is predominantly IEC 60664.

A good question then is, what do creepage and clearance distances mean for the end-product? For automotive high voltage battery management systems, the voltage breakdowns across an isolation barrier could result in damaging key safety mechanism in e.g. over-voltage detection and subsequently violating a safety goal. In medical devices a breakdown could result in the electrocution of a patient.

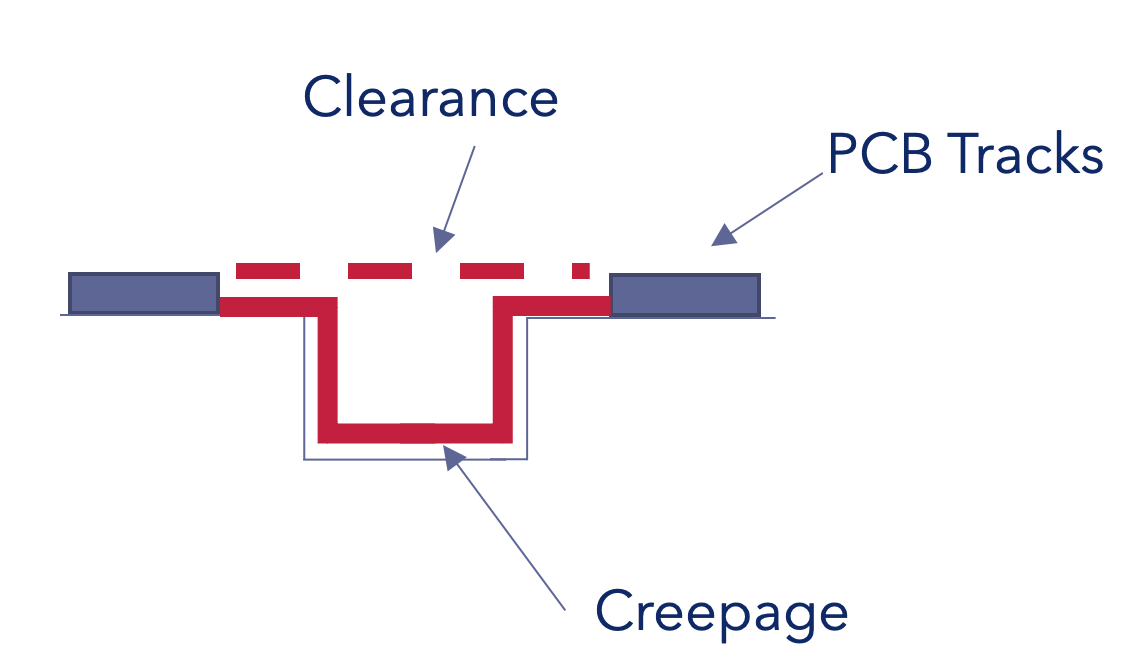

Fig. 1 illustrates the creepage path across the surface, in this case a printed circuit board (PCB) with a recess and the line of sight distance that is the clearance, through air. Many factors influence both the creepage and the clearance distance:

There are other factors that IEC 60664 addresses over and above these points, that also play a significant role:

We will take a look at these three additional factors in this blog.

Alastair Walker, Owner / Consultant

Explore our block of services on IEC 60664 insulation coordination. If you wish to take part in one of the courses or you are looking for consultancy in this area, please do not hesitate to contact us at info@lorit-consultancy.com.

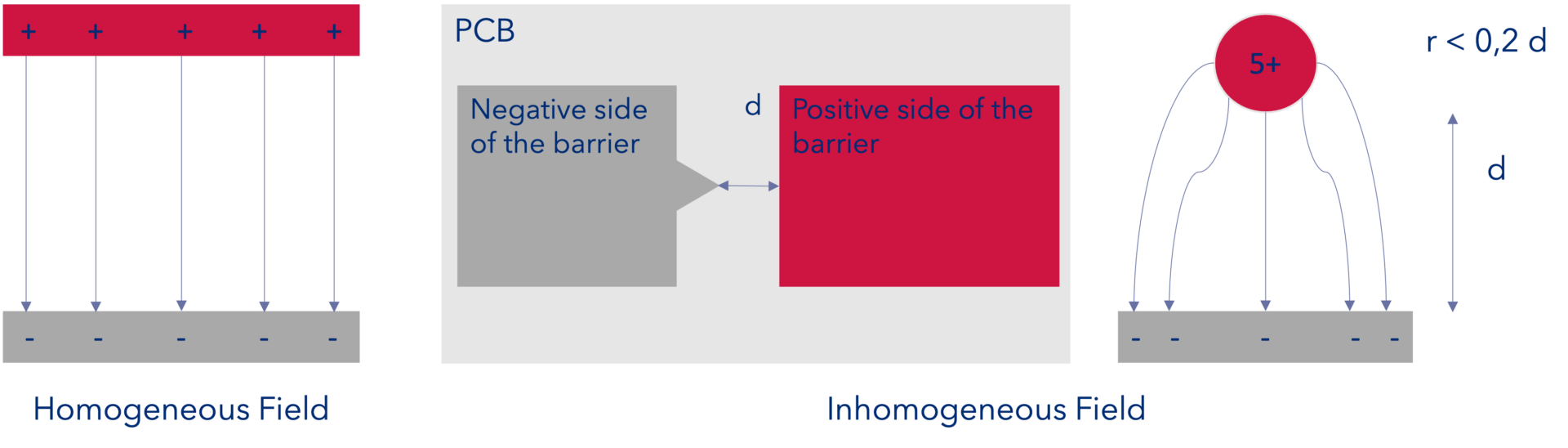

Erfahre mehrA topic that IEC 60664 brings into play is the difference between homogeneous and inhomogeneous fields. If two parallel conductors are implemented, then the field will be homogeneous; if we have a point protruding into the gap with a radius less than 20% radius of the gap distance, then we would have an inhomogeneous field. Whether a field is homogeneous or inhomogeneous has a significant impact on the clearance. In IEC 60664 for a 2,5kV impulse voltage we would need a clearance distance of 1,5mm for inhomogeneous, but for a homogeneous field this would only need to be 0,6mm.

Breakdown of isolation barriers with inhomogeneous field is where the term ‘corona’ comes into play.

Much of our recent discussions in high voltage automotive projects have focussed on the particle size that can potentially enter a ‘sealed’ enclosure.

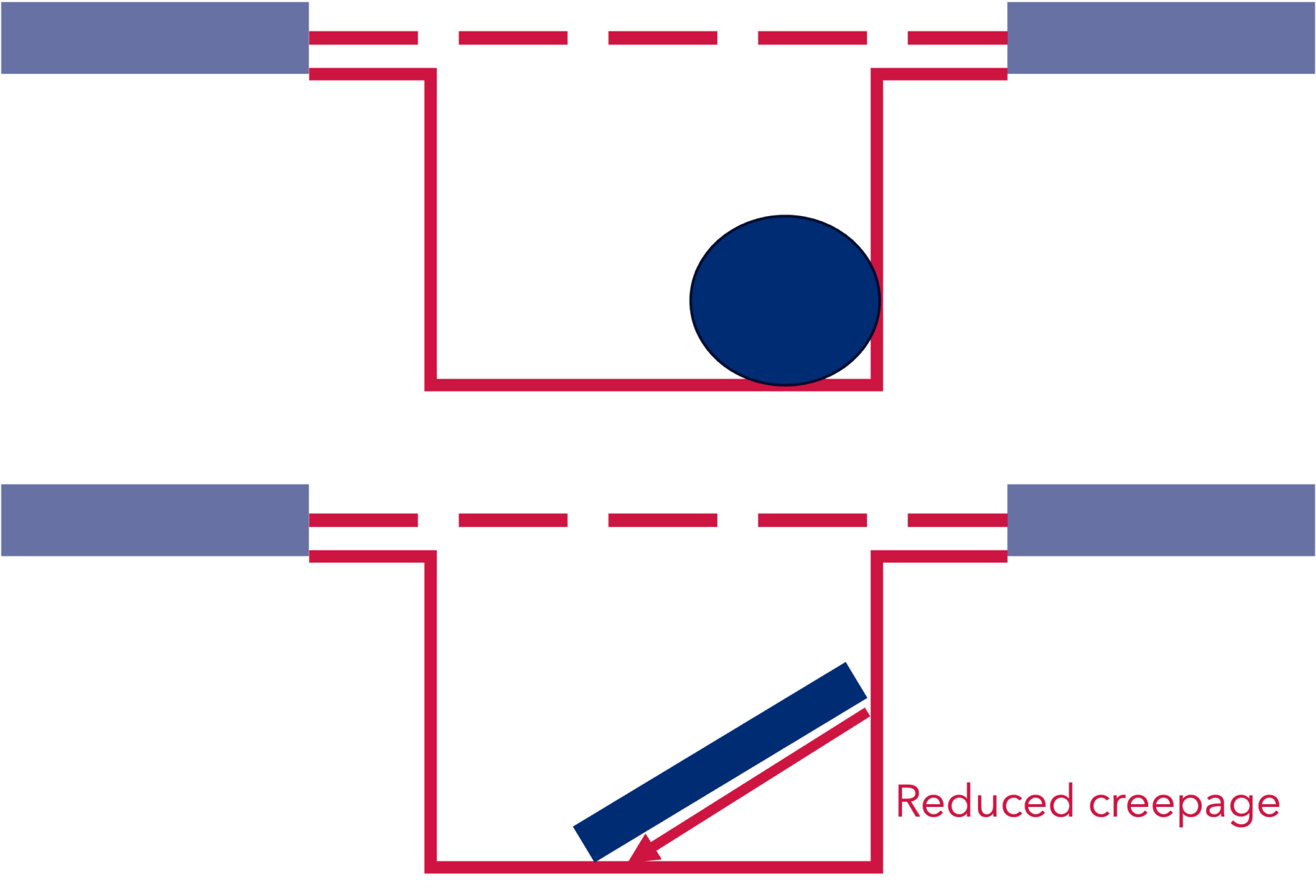

Reducing the pollution degree by sealing the enclosure can significantly reduce the creepage and clearance required, but the shape and size of the particle and where it might land (or be stuck) on a PCB plays a part.

Some fundamental questions arise here:

From Fig. 1 we then come to assess different particles and their impact. If the contaminating particle was of a much higher impedance than the material used for the PCB as in the top image in Fig. 3, this would not impact the creepage path, but the particle may be conduction and as in the bottom image this will reduce the length of the creepage path.

The properties of coating and insultation materials are well addressed in IEC 60664-3, the topic receives some good coverage in IEC 61010, but is covered to a minimal degree in IEC 60601.

Coatings come in two basic categories:

There are many types of conformal coating, liquid such as acrylic, silicone, polyurethane or epoxy resin. There are also more complex application coatings such as parylene (requiring specialist equipment).

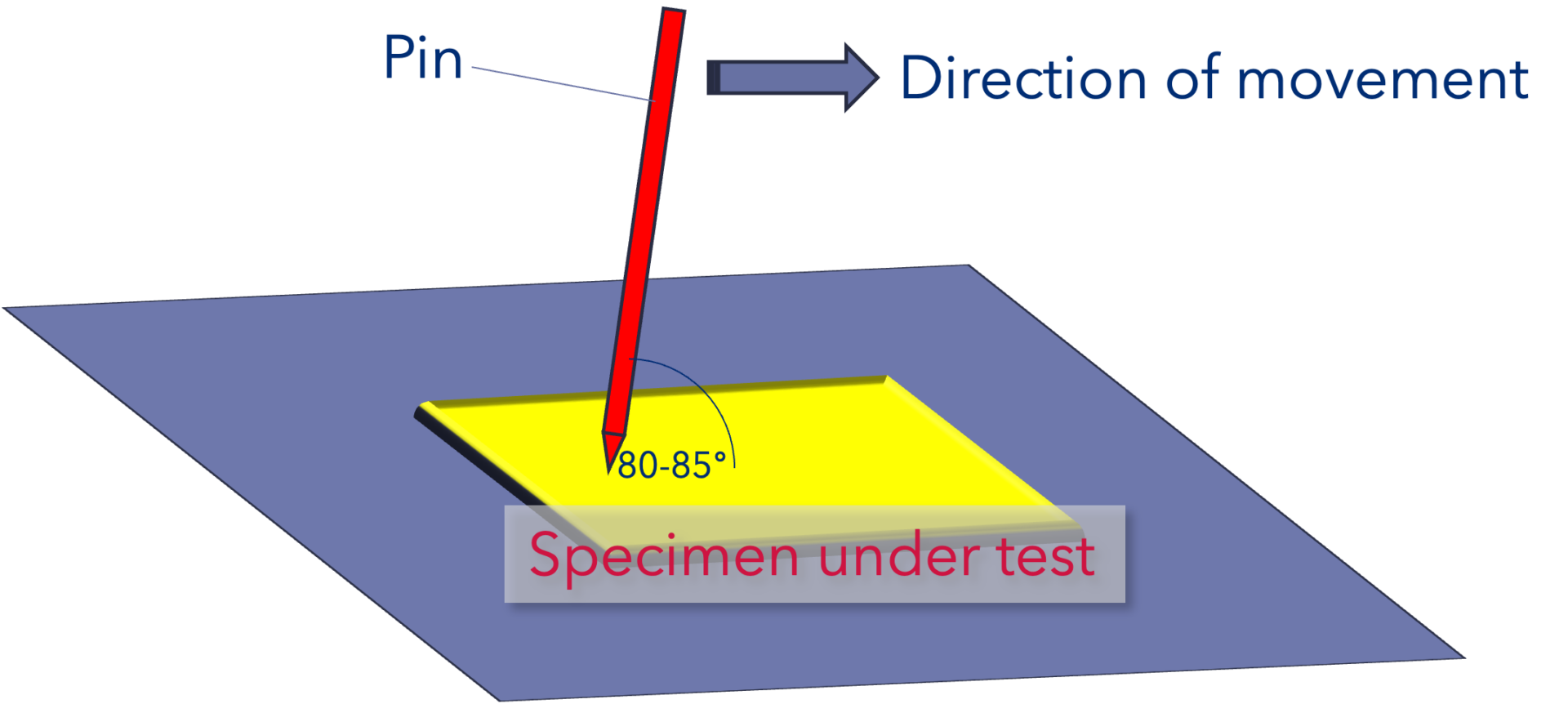

What is well addressed in IEC 60664-3 and to a lesser extend in IEC 61010, is how to test the quality of such coatings. For coatings to meet the requirements of IEC 60664-3 they need to pass:

The time to test all of these items takes many days, so compliance with IEC 60664-3 can be a costly process.

Related to the homogeneous/inhomogeneous subject, we come to our next topic. Having lived for many years not far from the house, where James Clerk Maxwell was born in Edinburgh, would be great to wax lyrical about the great work he did in the field of electromagnetism, but we would need several blogs just to scratch the surface (pardon the pun!). IEC 60664-4 brings in considerations of insulation where the frequency switching across the barrier exceeds 30kHz.

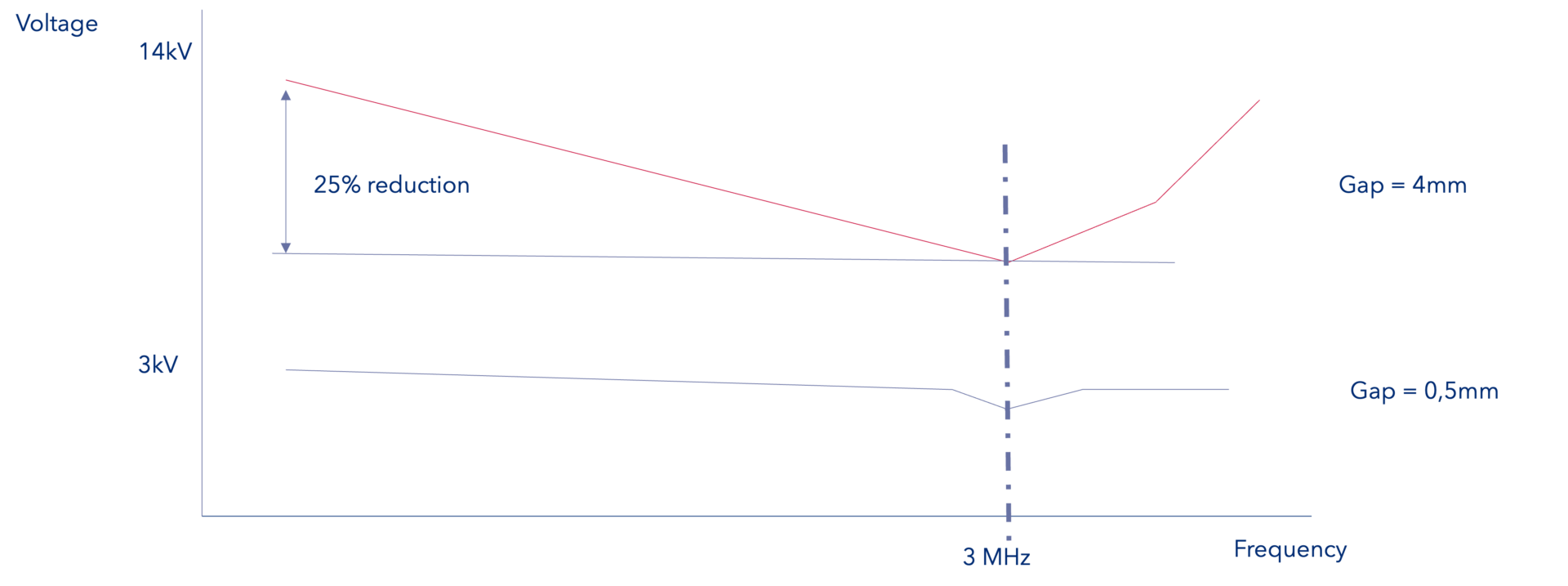

For homogenous fields, the isolation barrier can reduce by up to 25% as we approach 3MHz switching frequencies (see Fig. 5).

In the case of inhomogeneous, the reduction in breakdown voltage can be greater than 50% at higher frequencies.

Insulation coordination is a subject that impacts many industries and products, as we have briefly highlighted in this blog. There are many factors that influence the creepage and clearance and ultimately the design of the product. IEC 60664 really is the master source for many other standards and sheds a lot of light on the subject. With a new addition of IEC 60601 in discussion at the moment, there are some areas there that could be shored up. For automotive suppliers IEC 60664 remains the main reference for insulation activities.

By Alastair Walker, Owner / Consultant

If you would like to join one of our training courses or are looking for consultancy support in your functional safety-related projects, please do not hesitate to contact us via contact form or at info@lorit-consultancy.com.