VDA vs. IATF 16949: Understanding the Automotive Quality Landscape

With today’s blog post, we are launching an interesting blog series about the useful VDA volumes – both in relation to and as an alternative to IATF 16949:2016.

The German Association of the Automotive Industry (VDA) publishes a series of volumes (standards, guidelines etc.) and regulations that serve as standards and guidelines for the automotive industry, both in German-speaking countries and internationally.

These regulations cover various areas, including:

· Quality management

· Logistics and supplier management

· Sustainability and environment

· Product safety and development

These regulations are essential for many automotive suppliers and OEMs (Original Equipment Manufacturers) to meet the requirements of automotive manufacturers. Additionally, many of these standards are prerequisites for certifications and audits that automotive manufacturers require of their suppliers.

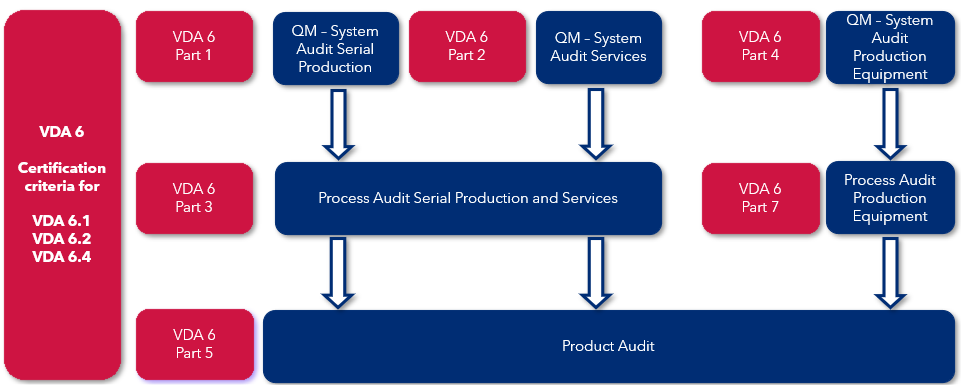

Figure 1. VDA QM System and QM Process standards (VDA 6.X series)

VDA 6.1 is an industry-specific quality management system that goes beyond the requirements of ISO 9001 and defines specific criteria for the automotive industry. It is primarily intended for manufacturers and suppliers that produce series and spare parts for the automotive industry.

The standard evaluates companies using a point-based system and covers various areas, including:

To obtain VDA 6.1 certification, a company must meet certain criteria, such as an implemented QMS according to ISO 9001, series production, and supplying the automotive industry, among others.

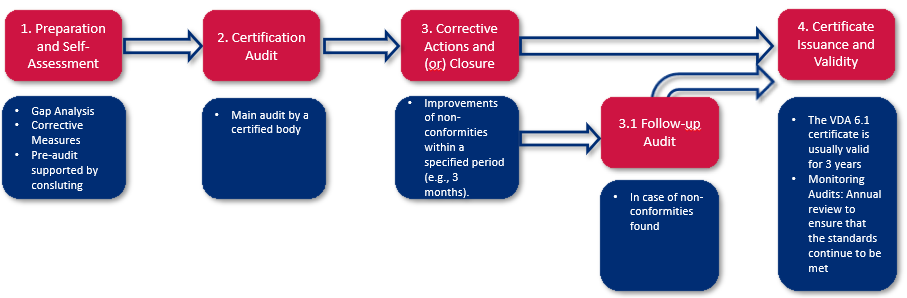

Companies seeking VDA 6.1 certification must undergo an audit. A point-based system is used:

· 90–100% = Certification passed

· 80–89% = Improvement required

· < 80% = Certification not passed

While there are options like VDA 6.1 or IATF 16949 for production sites, these standards do not apply to fabless companies. In this case, there is an interesting opportunity to certify such companies according to VDA 6.2 – Quality Management for Service Providers in the Automotive Industry.

Dijaz Maric, QM & Reliability Engineering Consultant

Do you want to learn more about the implementation of IATF 16949 or other standard in the Automotive sector? Please contact us at info@lorit-consultancy.com for bespoke consultancy or join one of our upcoming online courses.

Learn moreVDA 6.2 is a quality management standard, specifically for service companies in the automotive sector. While VDA 6.1 applies to manufacturing companies, VDA 6.2 is aimed at companies that provide services, such as:

· Engineering and development service providers (including system, hardware and software)

· Logistics companies

· IT service providers for the automotive industry

· Dealers, leasing companies, or workshops

· Customer service providers

While IATF 16949 is intended for manufacturing companies, VDA 6.2 remains the alternative for fabless service providers in the automotive industry. If your company provides services to automotive manufacturers or suppliers, a VDA 6.2 certification can be a competitive advantage.

E.g. BMW Welt in Munich as service provider, has certified its quality management system according to VDA 6.2.

VDA 6.4 – Quality Management for Production Equipment Manufacturers in the Automotive Industry is another QMS standard. It is specifically aimed at machinery and equipment manufacturers, as well as tool manufacturers, who work for the automotive industry.

The quality management system standards VDA 6.1, VDA 6.2, and VDA 6.4 are commonly referred to as the “VDA 6.X Standards.” Strictly speaking, there are additional standards or regulations within the VDA 6.X series, but certification is only possible according to the three above mentioned standards.

Thus, we come to the end of the first part of this blog series, where we discussed the QMS standards according to VDA and their relation to, and in some cases, role as an alternative to IATF 16949. How widely these are applied in practice remains questionable, and we will evaluate this once again at the end of the blog series.

In the next part of the blog, we will take a look at the process audits according to VDA 6.3 and the product audit VDA 6.5, which have become standards in the automotive industry and are required by every OEM, and IATF 16949 auditors. Stay tuned!

By Dijaz Maric, Quality Management & Reliability Engineering Consultant

If you are looking for quality management support either through consultancy or training courses, please feel free to contact us via contact form or at info@lorit-consultancy.com.