Does size really matter?

This blog does not cover what you might be thinking when reading the title!

The focus today is a less jovial topic meeting the challenges of electrical isolation barriers. Specifically requirements from customers in automotive projects may challenge the physical achievable spacing that is possible across printed circuit boards and components. The point that is perhaps not so clearly defined in standards such as IEC 60664 is that we are not constrained by the size of the gap across an isolation barrier. Other standards bring more clarity to the subject.

In this blog we look at ways we can bring alternative strategies into meeting the isolation challenge.

In our recent blog we looked at the concepts behind IEC 60664 and electrical insulation. The focus of IEC 60664 is on either meeting the insulation barrier requirements by introducing adequate creepage and clearance distances across components and barriers, or by using solid insulation that has very high insulation properties.

As we covered in the ‘IEC 60664 The Fountain of Knowledge’ blog, various factors can reduce the insulation properties, e.g. contamination, which increases the pollution degree, increased altitude, which reduces the insulation above 2000m, or the comparative tracking index, which gives a measure of how much current will flow across the surface of a material (how much it will track) when applying a given test voltage.

When all these factors are specified by say an automotive OEM, these can often result in serious technical challenges when double insulation requirements must be met, e.g. double the test voltage needs to be applied. For isolation components such as gate drivers, you may have a creepage distance of 8mm across the chip. For double insulation dependent on the insulation requirements and the various environmental factors, the required creepage distance may be greater than this.

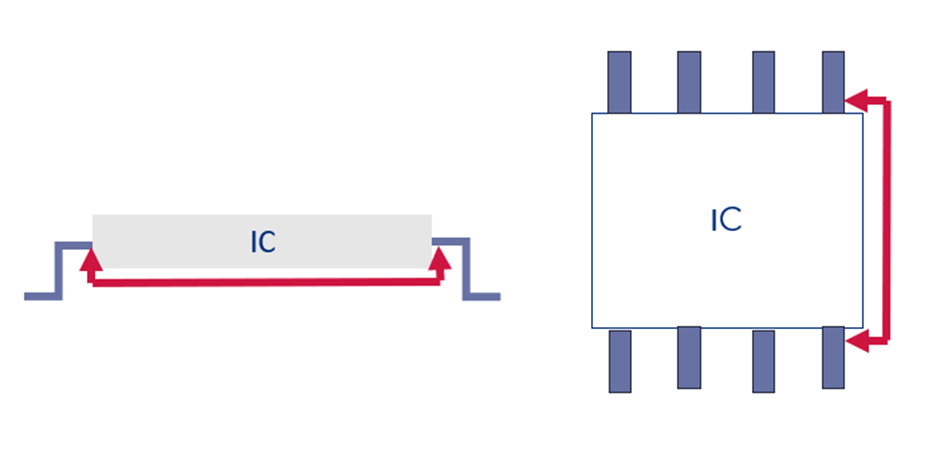

Figure 1 Creepage distances around ICs

As indicated in Figure 1, and often well supported by information by IC manufacturers datasheets, the creepage around ICs can take different paths and the worst case can sometimes be a shorter distance than the double insulation requirement for the project, so how do we address the challenge?

One solution might be to reduce the pollution degree on the PCB by adding conformal coating, but this can be a costly process. So let’s look at other options.

Measurement is the strategy for determining adequate the insulation distances in a device or product, rather than focussing purely on the individual creepage distance. In IEC 60664 solid insulation is tested using either an AC or DC test voltage. The latter defines specific breakdown currents (tripping current) that are typically 100 mA at 6 kV or this level can be reduced to 10 mA, based on specific test requirements.

One thing that is not so clearly defined in IEC 60664, is that tests can be complied with, if introducing additional impedance that limits the tripping current of generator when applying high voltage DC tests. This is obviously dependent on a number of factors; can a suitably high impedance be introduced in the circuit without impacting the product performance, or could this be realized by an addition of solid insulation.

Alastair Walker, Owner / Consultant

We have recently launched our new block of services on IEC 60664 insulation coordination. If you wish to take part in one of the courses or you are looking for consultancy in this area, please do not hesitate to contact us at info@lorit-consultancy.com.

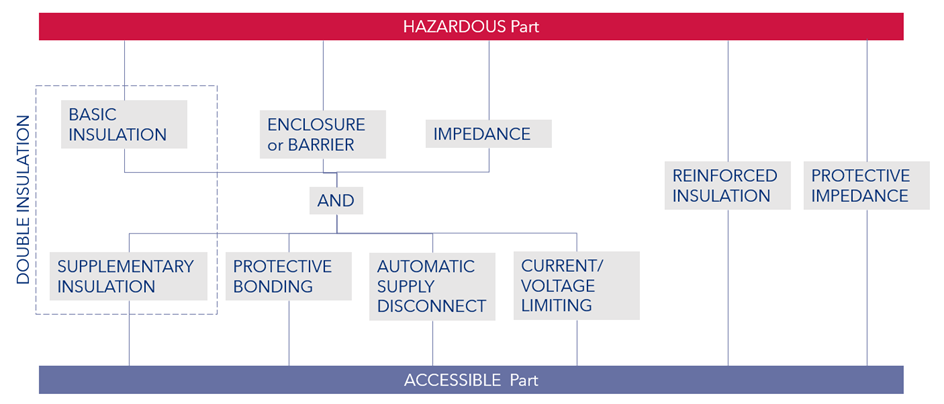

Learn moreThe approach in IEC 61010 to this topic is a good one, as shown in Figure 2.

Figure 2 IEC 61010 Meeting Insulation Requirements

In this way, double insulation can be realized by a combination of different techniques: supplementary insulation may be a creepage distance and an impedance introduces the second mechanism yielding the double insulation requirement. Hence, the insulation requirement may be met by 2 different technical solutions rather than on relying purely on a double insulation that meets the sizing requirements of the creepage.

Insulation can be a challenging topic, particularly if the demands of the stakeholder needs for excessive insulation distances. However, IEC 60664 does not specify how the requirements shall be met and a combination of mechanisms such as creepage and impedance, can yield a gut solution for meeting the insulation challenges. High voltage tests with specific tripping currents in the test generator being the measure of success.

Alastair Walker, Owner / Consultant

If you would like to join one of our training courses or are looking for consultancy or support in your functional safety-related projects, please do not hesitate to contact us at info@lorit-consultancy.com.

We look forward to hearing from you.

Address Austria:

Lorit Consultancy GmbH

Siezenheimer Straße 35

5020 Salzburg / Austria

Address UK:

Lorit Consultancy Ltd

1 Craigathie Road

Roslin Midlothian / Scotland EH25 9BG