Product and process release

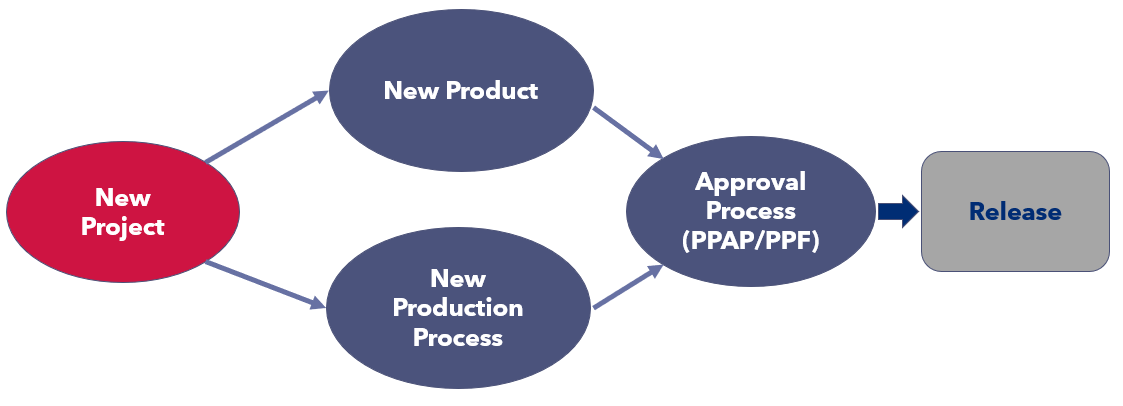

Before a product is delivered to the market or to the customer in series production, it must undergo an approval process. This relates to both the product and the production processes.

The release process must accordingly be planned as part of the early project planning phase and assigned to the corresponding milestones. The correct release strategy should be planned, and a representative should be appointed to take responsibility for the entire process. Typically, this is a quality engineer who is part of the project team and can regularly report on the status of the release process in team meetings.

The customer should be involved as early as possible, as they ultimately need to provide approval for the proposed release strategy. This is crucial for new products or production processes.

It is important to mention that the necessary resources for the release processes must be provided within the company. This applies to both human and material resources. For process approvals, it is crucial that process capability analyses are conducted by experts who are well acquainted with both the analysis methods and the production processes themselves. Typically, a team of several individuals is assembled to perform the defined tasks. In the case of product approvals, it is important to utilize the required equipment according to specifications during the approvals. For instance, equipment such as 3D measurement devices can be used to measure and approve product dimensions with the required accuracy. Such devices are not inexpensive, and if they are not used regularly, there is the option to conduct the product measurements required for approval through a licensed external provider.

The product release process is also covered in our IATF 16949 training course, full of details and practical examples. You can also contact us and request your own personalized requirement training course or consulting services.

Learn moreThe IATF 16949:2016 standard requires a documented product and production process approval (initial sampling) in Chapter 8. Approval must be obtained at the customer’s request before the product is delivered in series. Product approval should only occur after verification of the production process.

Picture 1: Initial Sampling

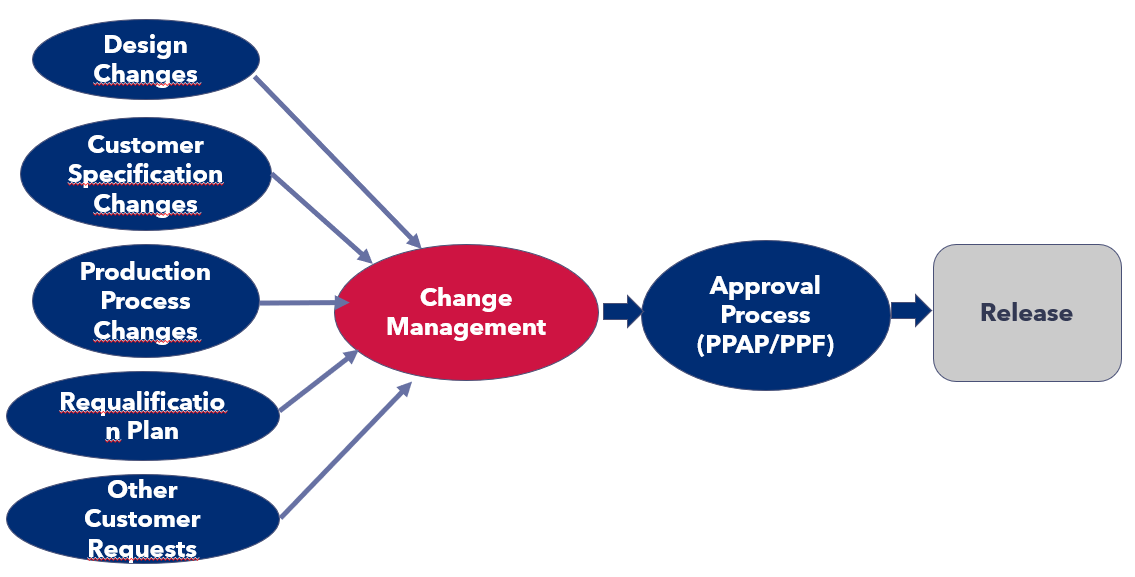

In the case of initial sampling, a distinction is made between initial sample testing, i.e., the first-time production of the products to be sampled under conditions similar to series production, and possible subsequent sampling in the following cases:

•Developmental changes after the initial product and production approval

•Specification changes

•Modification or introduction of alternative control and monitoring methods in the production process (Control Plan)

•Planned requalification tests

Other customer requirements such as logistics (Run at Rate)

Picture 2: Sampling after SOP

Records of product and production process approvals must be retained for a defined period. This period includes the entire production duration and the provision of spare parts, plus one calendar year unless there are other agreements with the customer.

Further details regarding the requirements can be found in the IATF 16949:2016 standard or through participation in our IATF 16949:2016 training.

IATF 16949 refers to the following methods of product or production process approval:

– AIAG – PPAP: Production Part Approval Process

– VDA Part 2 – PPA(PPF): Quality Assurance for Supplies Production process and product approval

Nowadays, the reference manual from AIAG (Automotive Industry Action Group) is more commonly used as a guideline or reference for approvals. The VDA (Association of the German Automotive Industry) even refers to the AIAG-PPAP reference manual in VDA Volume 2.

By Dijaz Maric, Quality Management & Reliability Engineering Consultant

We will provide more details about the individual methods in the next blog post, or you can always send an inquiry to info@lorit-consultancy.com regarding our IATF 16949 course, which can be tailored to the participants’ needs and places a special focus on the methods for the approval process PPAP/PPF.